- Products

- Catalogs

- News & Trends

- Exhibitions

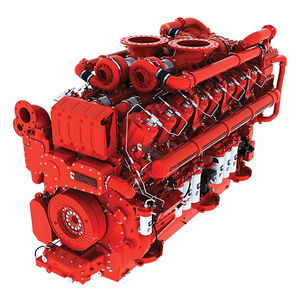

Inboard engine QSB seriespropulsionauxiliarydiesel

Add to favorites

Compare this product

Characteristics

- Type

- inboard, propulsion, auxiliary

- Power source

- diesel

- Market

- boating, professional vessel

- Technology

- turbocharged, common-rail

- Engine type

- in-line

- Rotation direction

- left hand

- Pollution control standard

- Tier 3, Tier 2

- Power

Max.: 550 ch

(550 hp)Min.: 230 ch

(230 hp)- Displacement

7 l

(2 gal)- Number of cylinders

6 unit

- Engine speed

Max.: 3,300 rpm

(20,735 rad.min-1)Min.: 1,500 rpm

(9,425 rad.min-1)- Bore

107 mm

(4.2 in)- Stroke

124 mm

(4.9 in)- Length

1,264 mm

(50 in)- Width

911 mm

(36 in)- Height

857 mm

(34 in)- Weight

658 kg

(1,451 lb)

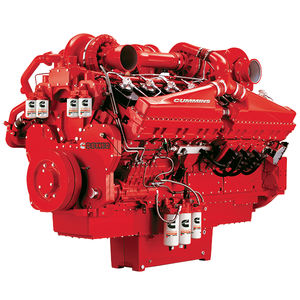

Description

Quiet operation, including an 80-percent reduction in noise at idle, is one of the many benefits from the common-rail fuel system

Enhanced sociability from the high-pressure common-rail design virtually eliminates smoke and improves the whole boating experience

Maximize vessel performance and access comprehensive vessel diagnostic information via SmartCraft® electronics

Peace of mind delivered by the Cummins Captain’s Briefing and global service network

Built at Darlington Engine Plant in Darlington, U.K. and Rocky Mount Engine Plant in Rocky Mount, NC, U.S

Engine Design – Unmatched performance driven through a perfectly matched turbocharger and a new 24-valve cylinder head that delivers industry-leading power density. Maximize vessel performance and access comprehensive vessel diagnostic information via SmartCraft® electronics. Peace of mind delivered by the Cummins Captain’s Briefing and global service network

Fuel System – Bosch HPCR with hardened components to safely operate alternative fuels such as kerosene and JP8/JP5. Quiet operation, including an 80-percent reduction in noise at idle. Enhanced sociability virtually eliminates smoke and improves the whole boating experience.

Lubrication System – Front-mounted filters. Oil service interval increased to 500 hours if using ULSD fuels

Cooling System – Single loop, low temperature aftercooling eliminates the need for two keel coolers and lowers emissions. Tube and shell heat exchanger designed for superior durability and ease of service with minimal maintenance requirements. Fan drive available for radiator cooled configurations

VIDEO

Catalogs

QSB6.7 Quantum Series Engine

2 Pages

QSC8.3 Quantum Series Engine

2 Pages

QSM11 Quantum Series Engine

2 Pages

Exhibitions

Meet this supplier at the following exhibition(s):

Related Searches

- Inboard motor

- Commercial motor

- Diesel motor

- 4-stroke motor

- Turbocharged motor

- Diesel generator set

- Professional vessel motor

- Propulsion motor

- Direct fuel injection motor

- Boat generator set

- In-line motor

- Common-rail motor

- 50 Hz generator set

- Ship motor

- Tier 3 motor

- Auxiliary motor

- Yacht generator set

- V motor

- Generator set with alternator

- Left hand motor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.