- Equipment

- Propulsion, Engine controls

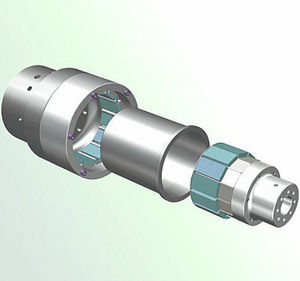

- Flange mechanical coupling

- jbj Techniques Limited

Flange mechanical coupling Hercuflex ®torsionally rigidfor boatfor ships

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Type

- flange, torsionally rigid

- Application domain

- for boat, for ships

- Applications

- for shafts

- Other characteristics

- shaft-hub, torque, high-performance, ATEX, heavy-duty, flameproof, for explosive areas, high load capacity, large-size, disassemblable, high-speed, with braking wheel

Description

Hercuflex ® torsionally rigid, power transmission couplings which transmit torque between two steel gear hubs and the internal toothing of a steel drive sleeve. ATEX certification on request.

The new generation of the Gear Coupling. By incorporating the latest advances in Finite Element Analysis technology, Lovejoy has revolutionized the Gear Coupling. Increased nominal torque, larger maximum bore size and longer service life are just a few of the many advantages of the HercuFlex coupling. Despite the advanced nature of these improvements, the HercuFlex Gear Coupling still utilizes the standard AGMA flange interface to ensure field interchangeability.

Gear-couplings are the foremost coupling type. They can do things that many other coupling types are unable to perform, or that need expensive modifications and de-rating to function. Gear couplings have the highest power density, offer more variations, a wider size, torque, and bore capacity than any other coupling type. They are easily modified for shear pin service, floating shaft type, vertical applications, electrical isolation, limited end float, and can have a brake drum or disc added. While some features may be available on other couplings, it is typically easier and cost effective to modify a gear coupling. With all these advantages, the gear coupling is used on more applications versus the nearest competing coupling type.

Factors Affecting Selection

The following is a list of the information necessary to assist in making a coupling selection.

Not all of these items will come into play in all selection processes.

Catalogs

ALL STEEL GEAR COUPLINGS

34 Pages

Other jbj Techniques Limited products

bellhousings / couplings

Related Searches

- Motor reduction gearbox

- Boat reduction gearbox

- Ships reduction gearbox

- Coupling

- Shaft mechanical coupling

- Ship coupling

- Boat coupling

- Flexible mechanical coupling

- Rigid mechanical coupling

- Flange mechanical coupling

- Anti-vibration mechanical coupling

- Torque mechanical coupling

- ATEX mechanical coupling

- Elastomer mechanical coupling

- Shaft-hub mechanical coupling

- Torsionally flexible mechanical coupling

- Torsionally rigid mechanical coupling

- Compact mechanical coupling

- Non-lubricated mechanical coupling

- Compensating mechanical coupling

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.