- Ship and boat building >

- Materials and paints >

- Honeycomb panel

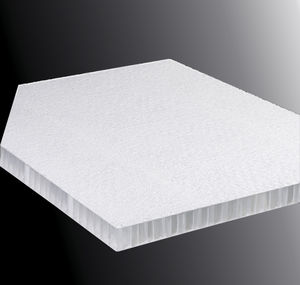

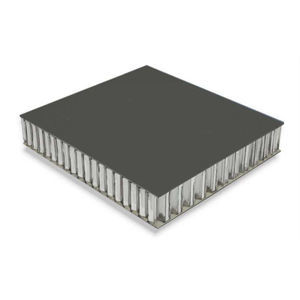

Honeycomb panels

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

... polypropylene honeycomb can also be used as support for filters to reduce corrosive gas emissions. Cel supplies different types of polypropylene honeycomb: • Polypropylene honeycomb ...

Nidaplast panels are honeycomb structures, made up of 8mm honeycombs, made of extruded polypropylene. The nidaplast 8RI is an ideal product for the infusion technique. Its specially ...

Nidaplast

Nestaplast panels are 8mm honeycomb structures. These polypropylene panels serve as the core of glued sandwich panels. Honeycomb core for gluing ...

Nidaplast

... characteristics. High density honeycomb panel The nidaplast 8HP honeycomb panels are manufactured at our industrial site in France, the sandwich panels ...

Nidaplast

The nidapan is a reinforced honeycomb panel, intended to serve as a rigid core of glued sandwich panels, rigid or lightweight ready-to-use panels. Their surface coating ...

Nidaplast

Nidaskin sandwich panels consist of a polypropylene honeycomb core, 8mm mesh. They have a previously glued skin on each side. Thermoplastic honeycombs are the result of the combination ...

Nidaplast

HONYLITE HPL–ALU Honeycomb Panel or High Pressure Laminate Honeycomb Panel is a sandwich panel bonded with high pressure laminate face material and with ...

Your suggestions for improvement:

Honeycomb material has an alveolar structure which is light and compression-resistant. It represents a good alternative to PVC foam.

ApplicationsThis material is used in the marine industry primarily as the core of a laminate sandwich for hull and deck construction. It also can be found in interior features.

TechnologiesAramid, polycarbonate, Nomex®, Kevlar®, polypropylene and even aluminum and other materials, each with its particular properties, are used to make honeycomb structures. For example, Nomex® is used in the great majority of American's Cup vessels and in ORMA-class trimarans. The material is usually resin-impregnated for subsequent use in a composite sandwich.

- Highly compression-resistant

- Very light alveolar structure

- Certain types very expensive

- Deteriorates when wet

the best suppliers

Subscribe to our newsletter

Receive regular updates on this section.

Please refer to our Privacy Policy for details on how NauticExpo processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining