- Ship and boat building >

- Materials and paints >

- Sandwich panel

Sandwich panels

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

Width: 600, 585 mm

Length: 3,000 mm

Thickness: 50, 100, 25 mm

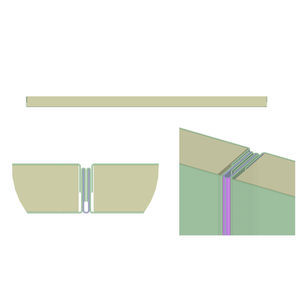

K-600 is designed with integrated joint profiles for rapid installation, leaving a flush surface with single seam joints. Available in standard or modular system. Approved B-15 available for several wall types. The ...

NORAC

Weight incl. joint profiles 25,5 kg/m2 Panel thickness 50 mm Panel width min. mm Panel width max. 600 mm Panel length max. 3000 mm Sound reduction Rw (lab) db

SBA Interior

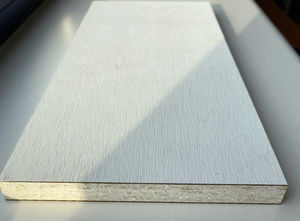

Width: 1,240 mm

Length: 2,480 mm

Thickness: 10 mm

This panel is constructed from a gypsum fiber core, fire retardant IMO certified, with HPL on both sides for finishing. The glue used for covering HPL is an IMO certified glue. The ceiling panels are ...

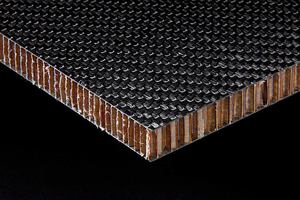

ship partition wall sandwich panelCOMPOCEL® AL FR

... shipbuilding, building and railway sectors. Our panels are produced according to the needs of our clients, who determine size and other panel characteristics. COMPOCEL ® AL FR A2 Panel ...

Cel Components s.r.l.

... pattern, etc.). As this panels is often used as flooring, where superior mechanical properties are required, the preferred thickness of the aluminium foil is 70 microns (high density), bringing the total thickness of ...

Cel Components s.r.l.

ALUSTEP® F is a lightweight sandwich panel with a core in aluminium honeycomb with two external layers in fibreglass reinforced with phenolic resin. Thanks to the low flammability of phenolic resin, this ...

Cel Components s.r.l.

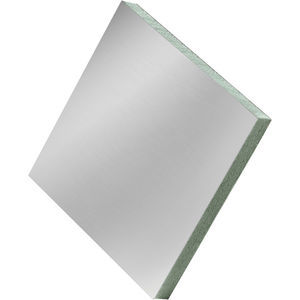

Width: 2,500, 3,000 mm

Length: 1,250, 1,500 mm

Thickness: 10, 15, 20, 25, 30 mm

... environments Countertops for industrial kitchens Support panel for facade cladding panel workability WORKABILITY Machinability with special tools for cutting steel behavior-moisture-panels MOISTURE ...

Isoleader s.r.l.

Width: 2,500, 3,100 mm

Length: 1,220, 1,530 mm

Thickness: 20 mm - 40 mm

Isoleader s.r.l.

Width: 2,400, 3,000, 4,000 mm

Length: 1,000, 1,250, 1,500 mm

Thickness: 10 mm - 40 mm

Isoleader s.r.l.

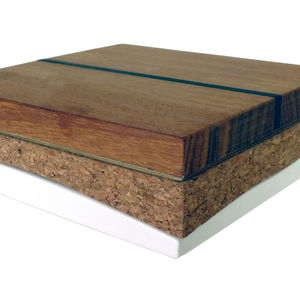

Kuiper Airex T-90 is a foam sandwich provided with okoume top layer. The AIREX® T90 is a closed cell thermoplastic and recyclable polymer foam with excellent fire, smoke and toxity (FST) properties. It has very good mechinical ...

Kuiper Holland - Superyacht Interior Panels

Width: 1,500 mm

Length: 3,000, 20,000 mm

Thickness: 5, 15, 12, 10, 6 mm

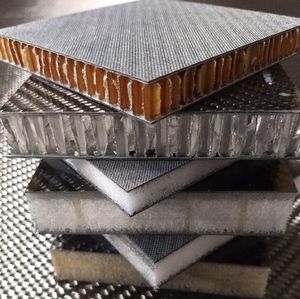

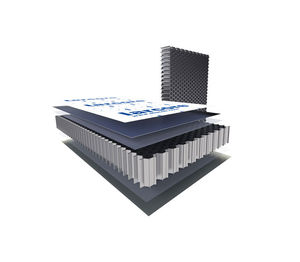

Metawell® is a patented aluminium lightweight panel, which is thanks to its sandwich structure very light and has a high bending resistance. Metawell® sandwich panels ...

Metawell GmbH- metal sandwich technology

Wall panels made with steel sheet / mineral rockwool / steel sheet sandwich in single configuration (25) total tickness 80 mm. A30 rated class (IMO Med) with joint elements on view (joint clips). Installation ...

Bimar

... range of sandwich panels is designed for applications requiring specific design needs, such as in various sectors. All our sandwich panels are tailored to meet design ...

Length: 3 m

Thickness: 6 mm - 24 mm

CompoLite®, a surprisingly light-weight and dimensionally stable sandwich panel made of composite material. CompoLite® can be perfectly combined with a variety of decorative materials. The properties ...

Width: 1,220 mm

Length: 2,440 mm

Thickness: 5 mm - 100 mm

Carbon Fibre Foam Core Sandwich Panels consist of two thin carbon fibre skins that ‘sandwich’ an ultra low density closed cell IPN or PET core. Thickness range: 6mm to 100mm Dimensions: ...

Juno Composites Ltd

Width: 1,200 mm

Length: 2,400 mm

Thickness: 10, 20, 30 mm

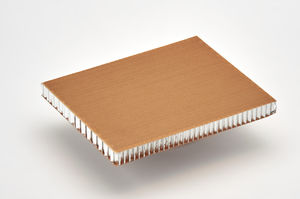

... developed for high-performance marine vessel interior applications AYRLITE® 2054 is a fully certified aluminium honeycomb panel with decorative laminate faces reinforced with aluminium sheet. Strain-hardened hexagonal ...

Ayres Composite Panels

A tough fibreglass cloth, with a sealed metallised skin, so it cannot absorb oil. Heavy duty in appearance and fire zero rated, the insulation will not tear or fray.

IMO/MED Certified With the development of the breakthrough ACM30 material, our engineers have brought a radical new product to life. ACM30 is a product certified with the Wheel mark symbol. The IMO/MED Wheel mark & USCG certification ...

Navicork by Amorim

Width: 120 cm

Length: 298 cm

Thickness: 40 mm

The fire-, heat- and noise-resistant composite sandwich triple-core panel FirePan 40/90 is made from non-combustible, environmentally friendly materials based on basalt fiber and ceramic matrix and impresses ...

lifeRock Group

Width: 1,220 mm

Length: 2,500 mm

Thickness: 15 mm - 78 mm

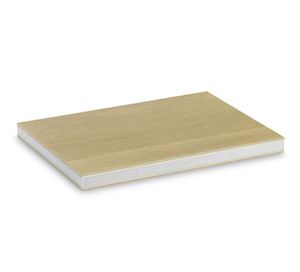

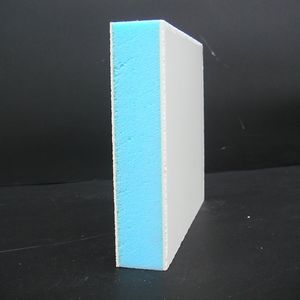

Ultra-lightweight sandwich panel for outdoor use, formed of an insulating XPS core — extruded polystyrene — and plywood that is exceptionally durable against weathering. The wood is modified using ...

Garnica Plywood

Thickness: 18 mm - 50 mm

LARICROSS®is a lightweight composite panel with both skins in Okoumé plywood and a core in STYROFOAM®and a rotary cut Okoumé ribs network that ensure high mechanical performances. LARICROSS®panel is ...

BELLOTTI SPA

Width: 1,500, 2,000, 1,000, 1,250 mm

Length: 2,000, 14,000 mm

Thickness: 6 mm - 40 mm

... studies to provide solutions for the different parts of large cruise liners, ferries, yachts and military ships. The larcore® panel is the perfect travel companion in the following applications: furniture, wall cladding, ...

The WET 5 panel has been designed as a complement for the wet areas of the CLIP 25 panel. The WET 5 panel is very similar to the CLIP 25 panel, with the only difference ...

PANELFA S.L.U

Sandwich panel: GRP laminates gelcoat finishes suitable to the contact with foodstuffs (on demand it is possible to deliver panels with different colours of GRP skins). Core foam: styrofoam.

T-PAN

... wood species. Moreover, the core of the panel is made of a special material which functions as an acoustic barrier. Upon request it is possible to realize the product with exterior layers on other wood-based panels ...

Compensati toro

... sound value of a wall allows evaluation of the direct transmission between one room and another. The value of Acoustiply panels between 2 rooms has been calculated in dB (A) for ‘Rose’ noise transmission ...

Acoustic sandwich panel recovered with a cut veneer decorative wood intended for the internal arrangement of boats.

Toubois

Soundown QuietCore Panels are composite panels consisting of high quality marine plywood skins sandwiching an acoustic core. The plywood skins constrain the acoustic core resulting in a panel ...

Soundown Corporation

ALUBEN™ is a composite panel made with a honeycomb core in Polycarbonate and two Aluminum layers 5/10 mm thick, treated with primer for Polyurethane adhesives. ALUBEN™ is used to support high-quality materials ...

Bencore S.r.l.

Your suggestions for improvement:

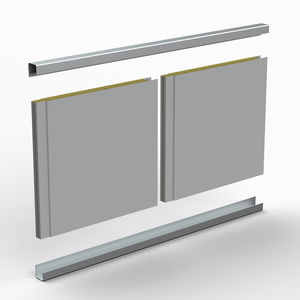

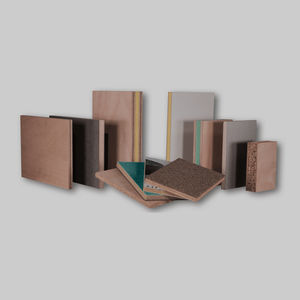

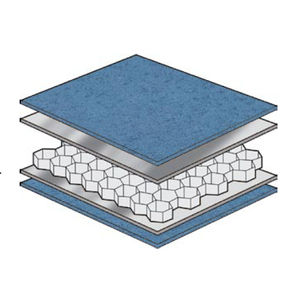

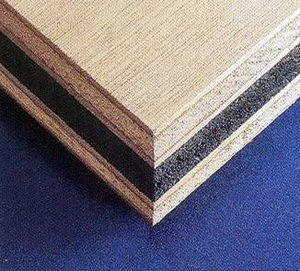

A sandwich panel is a composite element consisting of a core between two surface pieces.

ApplicationsThese panels are used to construct partitions, furniture, structural and interior elements. Though extremely light, they resist bending and shear forces. The core also may be fire-retardant or provide thermal or acoustic insulation. These characteristics make such panels suitable for a variety of marine construction applications including use by amateurs.

TechnologiesA structural element fastened at both ends and subject to perpendicular stress will sag to a degree proportional to the cube of the distance between the two support points. Stiffening can be achieved by using a more rigid material or by increasing the element's inertia, or quadratic moment, which is proportional to the cube of its thickness. The second, simpler solution is readily achieved by using a sandwich panel.

The core can be made from a variety of different materials including Core-cell®, honeycomb, PVC foam, rubber and balsa. Aluminum, wood, steel, laminated composites and other materials are used for the outer layers.

Panel characteristics will vary with the constituent materials of the core and outer layers. Choice will depend on precise use and environment. The stiffness-to-weight ratio is an important criterion.

- Excellent stiffness-to-weight ratio

- Rapid installation

- Expensive

the best suppliers

Subscribe to our newsletter

Receive regular updates on this section.

Please refer to our Privacy Policy for details on how NauticExpo processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining