- Ship and boat building >

- Production machines and tools >

- Vertical machining center

Vertical machining centers

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

{{product.productLabel}} {{product.model}}

{{#if product.featureValues}}{{product.productPrice.formattedPrice}} {{#if product.productPrice.priceType === "PRICE_RANGE" }} - {{product.productPrice.formattedPriceMax}} {{/if}}

{{#each product.specData:i}}

{{name}}: {{value}}

{{#i!=(product.specData.length-1)}}

{{/end}}

{{/each}}

{{{product.idpText}}}

The NE Series machining centers are designed and built in the United States, can be custom configured to offer broad industry applications. NE Series features a compact CNC machining ...

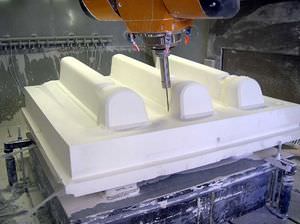

... developed a powerful machine concept for complex machining. The range of services covers processes from machining standard geometries and pre-finishing contours to final finishing. For dynamic machining ...

Starrag

... between complete, 5-side or 5-axis machining.For applications in the aerospace industry, Scharmann can also configure the ECOFORCE with a vertical machine table. The vertical alignment ...

Starrag

... between complete, 5-side or 5-axis machining.For applications in the aerospace industry, Scharmann can also configure the ECOFORCE with a vertical machine table. The vertical alignment ...

Starrag

... between complete, 5-side or 5-axis machining.For applications in the aerospace industry, Scharmann can also configure the ECOFORCE with a vertical machine table. The vertical alignment ...

Starrag

... control systems and milling units appropriate to their individual tasks. The flexible D40 ram-type milling unit with its integral C-axis, provides a stable platform for our wide range of milling ...

Starrag

... easily to any machining task.Optional automatic milling head, spindle and tool changing units enable complex and demanding machining routines to be performed. Due to Droop+Rein’s extensive ...

Starrag

New range of machining centres including 3 or 5 axes. Its structure is compact, powerful, versatile and easy to handle for the machining at high speed of non-ferrous materials (technical plastics, thermoformed ...

BERMAQ

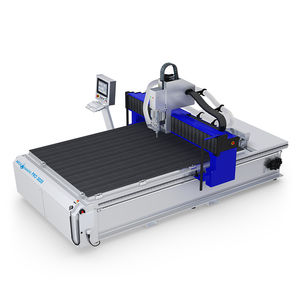

The CNC milling machine SG-5 from BERMAQ® has been designed to process a wide variety of materials such as aluminum, composites, plastics, acrylic, wood, resins, polystyrene, solid surface, etc. It is an ideal milling machine ...

BERMAQ

The BERMAQ® SG-3 CNC milling machine is the perfect tool for machining a wide variety of materials, in particular polystyrene, plastics, resins, etc. This milling machine has been ...

BERMAQ

... makes the ROCKET vertical CNC milling machine one of the best options on the market for the precision production of components in CNC operations. This machine allows you to achieve optimum finishing quality ...

BERMAQ

The CNC milling machine VISCOM is ideal for cutting, engraving, milling and rectifying different materials such as plastics and derivatives, acrylic, wood, foam, resins, non-ferrous materials, etc. This ...

BERMAQ

The CR milling machine has been specially designed for the machining at high speed of non-ferrous materials such as wood, aluminium, polystyrene and resin. It is a robust and precise machine ideal for ...

BERMAQ

Computerised Numerically Controlled Milling Machine (CNC) specially designed for the machining of great variety of non-ferrous materials (polystyrene, wood and resins) at high speed. Its low bedplate ...

BERMAQ

CNC machining centre specially designed to machine high-speed technical materials such as aluminum, titanium, composites, resins, etc. Ideal machine for the production of models and milling of work ...

BERMAQ

... guidance concept and modular structure, the SG milling machine is the perfect alternative for the machining of large work pieces since it uses its scope as working area. Technical specifications: Milling ...

BERMAQ

... guidance concept and modular structure, the SG milling machine is the perfect alternative for the machining of large work pieces since it uses its scope as working area. Technical specifications: Milling ...

BERMAQ

... boring and grinding - downtimes for workpiece repositioning are eliminated. The vertical design of these Breton machining centres is the ideal solution for machining workpieces with ...

Breton

The 5-axis FLYMILL range of machining centres offers four models – FLYMILL 1000, 1300, 1600 and 2000. The main difference between the models is vertical and horizontal travel – 2,500mm, 4,000mm and 3,500mm ...

Breton

Rigidity and high dynamics are distinctive features of this this 5-axis machining centre making it ideal for machining a multitude of components and products at high speeds with maximum milling ...

Breton

Five axis gantry machining centre: high-speed precision machine for milling complex three-dimensional work-pieces which require accurate machining and continuous axis interpolation. MATRIX ...

Breton

Interpolated 5-axis high-speed machining centre, the ideal solution for milling medium size workpieces in steel, aluminium, composite materials and resin. Speed, flexibility and compact design: Matrix ...

Breton

BRETON launches EAGLE, a new range of machining centres with a gantry design and highly-dynamic mobile crossbeam specifically designed and developed for machining composite materials, resin, light ...

Breton

The is machining centre is designed for machining complex 3-D components for the aerospace industry. Rigidity and high dynamics are distinctive features of this range making it ideal for machining ...

Breton

Designed for fine, precise, intensive works in small formats, the CharlyDMCII milling machines are used for many applications: metal engraving, fine machining, plasturgy, design, rapid prototyping, electronics… STRENGTHS • ...

MECANUMERIC

MECAPRO For professionals, this 3 axis CNC milling equipment range offers an excellent price ratio/performances, in many industrial sectors. Precision milling/cutting machine (router) with simple use for machining ...

MECANUMERIC

MECAPLUS Optimized for machining aluminium, plastic materials in strong thickness and composite materials with high mechanical characteristics. Precision milling machine of simple use for machining ...

MECANUMERIC

Thanks to their simplicity of use, to their amazingly fine milling results and to their wide surface of milling, the charly4U/2U are a reference in their field with their capacity to mill metals such as aluminium, brass, ...

MECANUMERIC

... demanding productions in 2D as in 3D STRENGHTS Mono-bloc frame in high inertia welded steel and mobile gantry in steel. Milling speed up to 18m/min Plate : fixed table made of wide section of aluminium profiles ...

MECANUMERIC

... with small thickness (PVC, PS, PET, PETG, ABS, PC…) STRENGHTS : VERSATILE AND CUSTOMIZABLE EQUIPMENT : High-speed machining (HSM) Secondary pre-installed functions (heads non included): knife-cutting with tangential ...

MECANUMERIC

MECAPLUS HP MECAPLUS-HP “AGILE” MACHINING High precision and performance solution HIGH PRODUCTIVITY 3 axes milling equipment : “AGILE” MACHINING STRENGTHS Designed and ...

MECANUMERIC

... Side windows Aircraft interior furnishing Parts for the train industry Parts for racing motorcycles MILLING EQUIPMENT OPTIMIZED FOR THE MACHINING OF BIG FORM PARTS REALIZED BY THERMOFORMING PROCESS ...

MECANUMERIC

... the train industry Parts for racing motorcycles Realization of models and moulds or 5 axes machining of vacuum formed, rotomoulded form parts… MILLING EQUIPMENT OPTIMIZED FOR FOLLOWING MATERIALS: . ...

MECANUMERIC

Your suggestions for improvement:

the best suppliers

Subscribe to our newsletter

Receive regular updates on this section.

Please refer to our Privacy Policy for details on how NauticExpo processes your personal data.

- Brand list

- Manufacturer account

- Buyer account

- Our services

- Newsletter subscription

- About VirtualExpo Group

Please specify:

Help us improve:

remaining