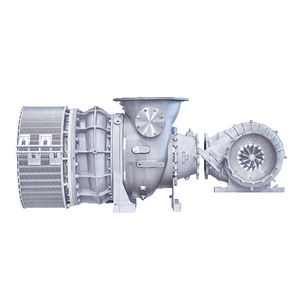

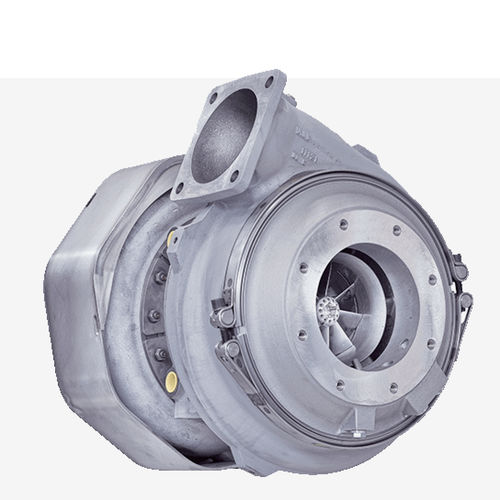

4-stroke turbocharger A100-Hcompacthigh-speedhigh-efficiency

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Options

- 4-stroke, compact, high-speed, high-efficiency

- Engine power

Max.: 6,000 kW

(8,158 hp)Min.: 500 kW

(680 hp)

Description

Pushing the boundaries of single-stage turbocharging

A100-H turbochargers are designed for high-speed diesel and gas engines, in applications ranging from 500kW to 6,000kW.

Cruise ships and ferries

The A100-H turbocharger can be used on cruise ships and ferries

Pressure ratio

Full-load pressure ratios up to 5.8

feature

Efficiency

66% turbocharging efficiency

feature

Cooling

Compressor wheel cooling for continued use of aluminium compressor wheels

feature

Shaft sealing

Advanced shaft sealing design reduces blow-by

feature

Adapt

Multiple compressor stages match all frame sizes

feature

Range

Mixed-flow turbine design offers extensive operating range

feature

Bearings

Water-cooled bearing casing enables higher exhaust gas temperatures

How A100-H helps you increase fuel savings and reduce emissions

Adopting the A100-H brings long-term benefits, including a low total cost of ownership. It matches the long maintenance intervals of TPS turbochargers, despite the higher demands on its thermodynamic and mechanical performance.

What to expect

With this benchmark-setting turbocharger, you’ll see greater reliability and less downtime. It’s specifically designed for easy maintenance, repair and overhaul, with long service intervals of up to 24,000 hours.

Engine power

A significant increase in engine power

Capability

Improved high altitude and ambient air temperature capability

Fuel efficiency

Improved fuel efficiency

Range

Optimum matching to a maximum range of applications

Catalogs

No catalogs are available for this product.

See all of Accelleron‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.