- Ship and boat building

- Production machines and tools

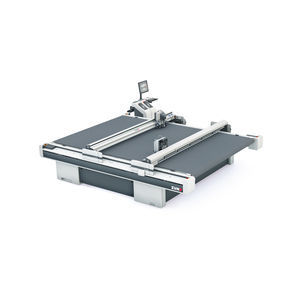

- CNC cutting table

- Zünd Systemtechnik AG

CNC cutting table L3for leatherfor shipyards

Add to favorites

Compare this product

fo_shop_gate_exact_title

Characteristics

- Type

- CNC

- Treated material

- for leather

- Application domain

- for shipyards

Description

Smart, efficient leather cutting: The L3 is perfect for the leather industry and is specifically designed for producing top-quality leather goods.

Produce high-quality leather goods

Take your productivity in leather manufacturing to the next level. Process leather, sole, lining, and stencil materials precisely and efficiently with the L3. The cutting system handles even highly complex patterns at exceptionally high speeds. Furthermore, because of its superior precision, time-consuming post-production finishing tasks have become a thing of the past.

L3 cutter overview

The 2 different cutter models of the L3 line let you select the perfect machine size for all your production needs. Our digital cutting systems are intelligent, efficient, and ready for the future.

Process leather, sole, lining, and stencil materials precisely and efficiently with the L3 cutting system. With the right tool, you can cut leather at speeds of up to one meter/40 in per second. With the L3 you can produce leather goods economically, efficiently, and at premium quality levels.

Zünd L3 – efficient, robust, powerful

The L3 is extremely fast and robust and gives manufacturers the ability to dramatically increase their output. The exceptional productivity of the cutter stems from its smart motion control, precise drive system, and fine-tuned cutting technology. Furthermore, with its superior precision, the cutter proves itself by immediately processing even highly complex patterns at exceptionally high speeds.

VIDEO

Catalogs

Zünd Corporate Magazine

32 Pages

Related Searches

- Shipyard cutting machine

- Electric cutting machine

- Textile cutting machine

- Cutting table

- Shipyard cutting table

- CNC cutting table

- Shipyard cutting tool

- Pneumatic cutting machine

- Rubber cutting machine

- Leather cutting machine

- Shipyard software

- Nesting software

- Straight-knife cutting machine

- Sail loft software

- Visualization software

- CNC cutting machine

- Laser cutting machine

- Foil cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.