- Harbors and port terminals

- Port equipment

- Harbor fender

- ShibataFenderTeam

- Products

- Catalogs

- News & Trends

- Exhibitions

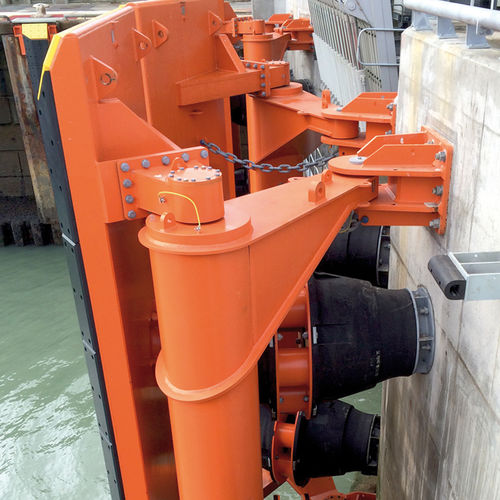

Harbor fender Parallel Motionpierparallel motion

Add to favorites

Compare this product

Characteristics

- Application domain

- for harbor

- Applications

- pier

- Other characteristics

- parallel motion

Description

Parallel Motion Fenders are individually engineered systems and could be designed with different rubber units, but typically with SPC Cone Fenders, CSS Cell Fenders or FE Element Fenders.

A turning lever arm (torsion arm) is mounted between the back structure (concrete or steel) and the frontal steel panel. The arm restrains the panel movement during the entire fender compression, allowing it to move only parallel to its mounting, irrespective of impact level and angle.

PM Fender systems have to be uniquely designed for each project in order to cover all the individual vessel and berthing requirements as well as the site conditions. ShibataFenderTeam would be pleased to receive your design input allowing us to engineer the correct type, size and overall layout of the PM Fender system.

The PM Fender system can be delivered pre-assembled, depending on size.

Characteristics

Equal energy absorption capacity at any impact level

No second contact point between the ship and the fender system

Reaction forces could be substantially lower for back-to-back rubber unit configuration

cost-effective: Lower reaction forces -> lower hull pressures -> lighter substructure

Usually no reduction of performance at large berthing angles

Applications

Bulk Terminals

Oil & Gas Terminals

Ferry & RoRo Terminals

Monopiles

Load sensitive structures

Catalogs

No catalogs are available for this product.

See all of ShibataFenderTeam‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.